Anova Gage R&r Template

Thank you everyone for your help.I entered my data into the excel Anova Spreed sheet. But this method shows that 'Gage needs improvement' I am attaching a copy of the resultsHow do we interpret the results? What needs to be improved?Can somebody verify with minitab or other software if my results are correct?Thank you so much for your help.CarolineGAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEETANOVA METHODPart Number Gage Name Appraiser A AnaNUMBERPart Name Gage Number Appraiser B EvaNAME xxxCharacteristic Specification Gage Type Appraiser C Sandy-1.51.5Characteristic Classification Trials Parts Appraisers Date Performed3 10 3APPRAISER/ PART AVERAGETRIAL # 01.

A1-0.70-0.92-0.23-1.02-0.94-0.52-0.89-0.25-1.01-1.01 -0.7492.2-0.72-0.90-0.23-1.03-0.94-0.52-0.89-0.25-1.01-1.01 -0.7503.3-0.70-0.90-0.25-1.00-0.94-0.52-0.89-0.25-1.01-1.01 -0.7474.AVE-0.71-0.91-0.24-1.02-0.94-0.52-0.89-0.25-1.01-1.01xa=-0.7495.R0.020.020.020.030.000.000.000.000.000.00ra=0.0096. B1-1.03-1.02-0.40-1.10-1.01-0.60-0.90-0.35-1.08-1.15 -0.8647.2-1.03-1.02-0.40-1.08-1.01-0.60-0.90-0.35-1.08-1.15 -0.8628.3-1.03-1.03-0.45-1.10-1.01-0.60-0.92-0.35-1.08-1.15 -0.8729.AVE-1.03-1.02-0.42-1.09-1.01-0.60-0.91-0.35-1.08-1.15xb=-0.86610.R0.000.010.050.020.000.000.020.000.000.00rb=0.01011.

C1-0.69-0.90-0.40-0.14-0.89-0.84-0.70-0.99-0.98-0.96 -0.74912.2-0.69-0.90-0.40-0.14-0.89-0.84-0.70-0.99-0.98-0.96 -0.74913.3-0.69-0.90-0.40-0.14-0.88-0.85-0.71-0.99-0.98-0.96 -0.75014.AVE-0.69-0.90-0.40-0.14-0.89-0.84-0.70-0.99-0.98-0.96xc=-0.74915.R0.000.000.000.000.010.010.010.000.000.00rc=0.00316. I do not have access to my analysis software at this time to validate your analysis, but I can provide feedback on the results. Search this forum and you will find a validation data set from Ford that you can used to validate the spreadsheet.As to your analysis:The ANOVA table shows statistical significance between operators (that Reproducibility) and an interaction between the Operators and the parts. This means that different operators measured different parts differently. This should show up in a graph.The MSA results show that your Repeatability (variation within the same operator) is the highest at 66.7% of the total variation. The interaction between operator and part was next at 43.8%, with the Reproducibility (variation from Operator A to Operator B) following at 19.3%You have problems with all three and the gage is of no use for process control at a%GRR of 69.4% and an ndc=1If you will provide information on the product, the characteristic measured and the measuring device, we can better help you. I could guess at some common issues, but I would rather get more specific for you.Repeatability issues are commonly (but not always) caused by variation in form of the part itself with no established method of measurement.

An example would be an oval shaft where one operator randomly measure the diameter. Throw in one operator that usually measures the max diameter and another that measures the max and min diameter then averages them and you have poor Reproducibility and a possible interaction.Poor part fixturing can also be an issue.Poor Reproducibility is typically caused by not having a clearly defined method of measurement.Again, these are common issues, but may not be your issue. I have been reading this discussion, and others, on ANOVA trying to understand it. I am trying to develop a MSA study at my facility and write up procedures and make a spreadsheet to perform the calculations.I have a questions regarding the degrees of freedom, I notice that in tedschmitt spreadsheet above there is a column in the ANOVA calculations for degrees of freedom. The equipment row states that there are 60 degrees of freedom, the same as is listed in the MSA manual. However, I cannot find any way that this is actually calculated.

Can someone please explain how the this particular degrees of freedom is found.Thanks.

.Why do we need MSA: Measurement System Analysis in Data Analyses?Hi, this is Mike Negami, Lean Sigma Black Belt.This time I received a video request from one of our viewers. “Please make a video on calibration?” “Calibration on Measuring gauges sir.” Thanks, sekhar. Calibration is to adjust the read-out deviations of measuring devices.It’s important to work on things scientifically, based on data. This is especially true in Lean Sigma and SPC: Statistical Process Control.

However, what if those data are wrong? All decisions based on those data would be mistakes and they will most likely cause failures. So, for SPC, it’s an imperative practice to ensure that you are collecting the correct data.Therefore, in SPC, we use MSA – Measurement System Analysis. I made an article about this topic in the past, so please click on the link below and read the article.How Gage R&R is used in BusinessI’ll introduce Gage R&R, the most common method of MSA. I’ll explain a very difficult topic in an easy-to-understand manner without using any formulas.

Gage R&r Acceptance Criteria

I made an Excel template, so I’ll explain this topic along with the template.When you conduct the Gage R&R, you can see if there is a problem with the operator or measuring device in your measurement system. If it’s your measuring device, you need to calibrate it.The method of calibration depends on each device. Also, depending on your industry, you may have a set standardization. For component manufacturing companies, their clients may require them to submit proof of their MSA.

At that time, they may submit their records of Gage R&R. Let’s look at the Gage R&R template now.Decide the measurement standard and start measurements using the Gage R&R Excel template.Click the link below to download the Gage R&R template.← Click this to download the “Gage R&R Using ANOVA” template file.On the right side of the template, it shows the instructions for how to conduct the Gage R&R analysis.First, decide the measurement standard. Usually three appraisers measure ten different parts 3 times each, but you may need to change that according to your industry or customer’s request. When choosing your parts, it may sound strange, but choose the parts so as to increase their variation. If your parts didn’t have enough variation and your measurements were all about the same, your analysis result would look worse than it actually is. The purpose here is not to make good products, but to find the good or bad of your measurement method. Also, have the people who normally do the job be the appraisers here.Next, have the appraisers measure each part in random order, and input all measurements into the “Sampling Measurement Results” section.

I’ll copy and paste my sample data here. Then the calculation results are already done below. Let Excel do the difficult calculations. Here is a data entry example below:What’s Gage R&R’s ‘Repeatability’ and ‘Reproducibility’?Gage R&R’s ‘R&R’ stands for ‘Repeatability’ and ‘Reproducibility’. For example, if the same appraisers measure the same parts with the same measuring devises, they should get the same measurements. However, if that’s not the case, its ‘Repeatability’ is bad. Also, we’ll consider their total variation as ‘Repeatability’.If other appraisers measure the same parts, they are supposed to obtain the same measurements as well.

Template For Gage R R Anova

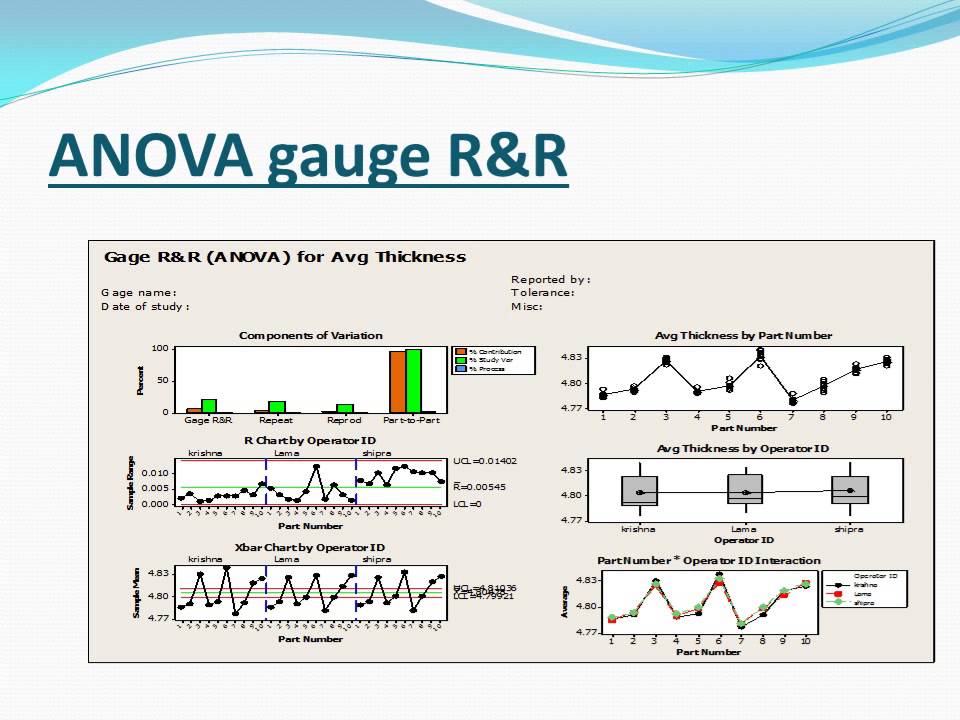

If that’s not the case, its ‘Reproducibility’ is bad. We’ll consider that variation among the appraisers’ averages as Reproducibility.Gage R&R’s Results and How to Interpret themThere are a few kinds of Gage R&R. This template uses ANOVA – Analysis of Variance. Generally speaking, this method is the most accurate.The 1st table in the image above is the result of ANOVA and the 2nd one is Gage R&R. I’ll give you a very rough explanation of what they have done. The sum of the variations of Repeatability and Reproducibility is called the Total Gage R&R. Then, by comparing it with the total variation, this appraises your measurement system as good or bad.The last section in the image above, ‘Statistical Interpretation’ is the most important.

It says 21.48% in yellow Cell P54. It means that the variation of your measurement system accounts for 21.48% against the total variation. The guidelines for each KPI are shown in the instructions, and each result is given in Cell O55 too.If it’s under 10%, your measurement system is acceptable, but if it’s 10% or more, you must improve it. In that case, Cells X43 and X44 turn blue. You should compare Repeatability and Reproducibility there.

Gage R&r Example Pdf

In this example, since the variation of Repeatability is higher, the advice given below is “Your measuring equipment may need calibration or maintenance.”Lastly from the result of the pink Cell P59, you are getting other advice. If this number is 5 or more, this analysis is reliable at this time.

But, if it’s 4 or less, the parts you used didn’t have enough variation. Use another set of parts.We discussed MSA‘s Gage R&R today.「こちらの記事も読まれてます 。 」.